Cell Therapy Development: End-to-End solution

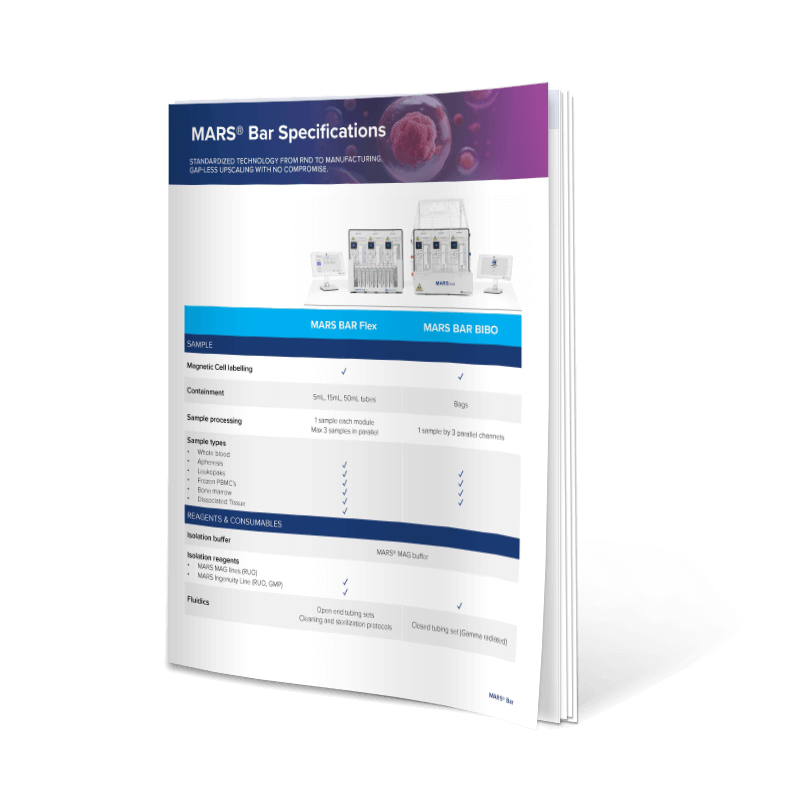

Standardize your process from Small to Large Scale Cell Isolation

CAR-T Therapy

In the past twenty years, T cell-based immunotherapies have greatly revolutionized the field of cancer treatment and enormous efforts have been devoted to developing new drugs as well as improving the efficiency of manufacturing processes. At AC, we provide researchers with technological solutions promising flexibility and scalability.

How we support you

Our Team

Our main drive is to help researchers achieve their goals, and transfer knowledge and experience, opening doors to new solutions.

Whether we are with a small research lab or supporting a cell manufacturing company, we are always looking for a way to innovate, improve the process and identify new opportunities. Our focus has allowed us to work on fascinating projects in the USA, Europe and Asia, and has led us to establish this end-to-end solution.

Every day we challenge ourselves to push the limits of what’s possible in MARS® platform development. Each team member and business partner brings a unique blend of talent, passion and expertise to the table, and we all share the values of the research community.

Our technology

MARS® Bar is an in-flow immunomagnetic cell isolation platform. It doesn’t require magnetic columns and enables the sterile collection of both positive and negative fractions in separate bags.

The platform enables an easy and flexible transition from RUO process development to large scale isolation.