GoFast™: accelerating the future of CAR-T cell therapy

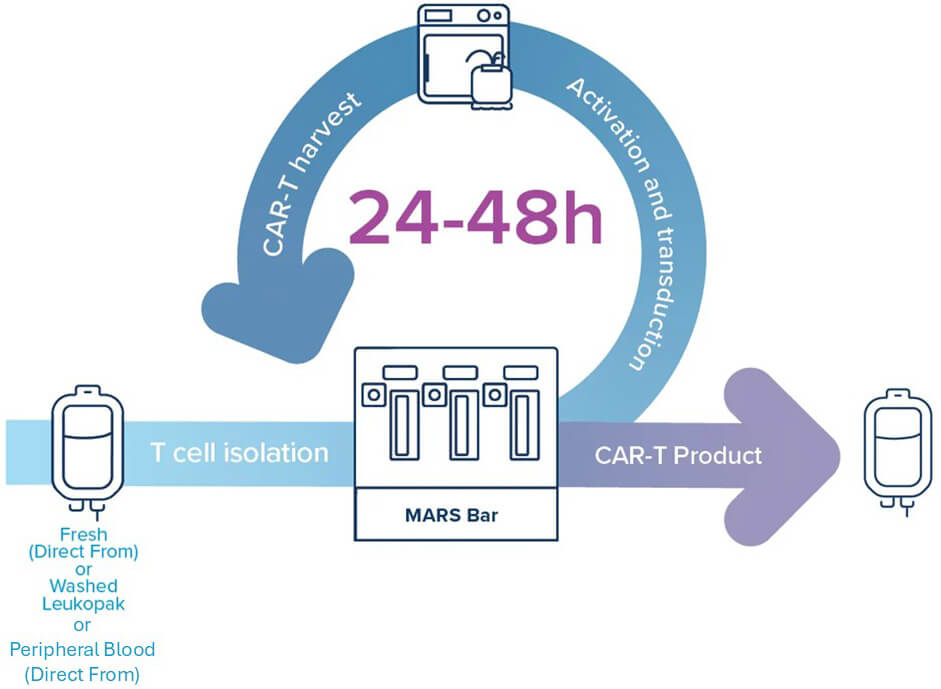

Enrich, harvest, and accelerate CAR-T development with a GMP-ready GoFast™ workflow – powered by the MARS® Bar platform to deliver CAR-T cells in under 48 hours.

Ready to GoFast™? Contact us!

GoFast™ – join us in our mission

Our mission is to enable scalable cell therapy manufacturing — with a vision to help reduce manufacturing COGS

below $10,000 with GoFastTM workflow.

Traditional CAR-T manufacturing takes 2–3 weeks, often delaying treatment for critically ill patients. GoFast™ reduces this timeline to under 72 hours, enabling faster delivery of life-saving therapy when every moment counts. Its streamlined, GMP-ready workflow also supports point-of-care manufacturing, paving the way for decentralized, more accessible treatment solutions.

WHY GoFast™ ?

A 3-Step GoFast™ CAR-T Manufacturing

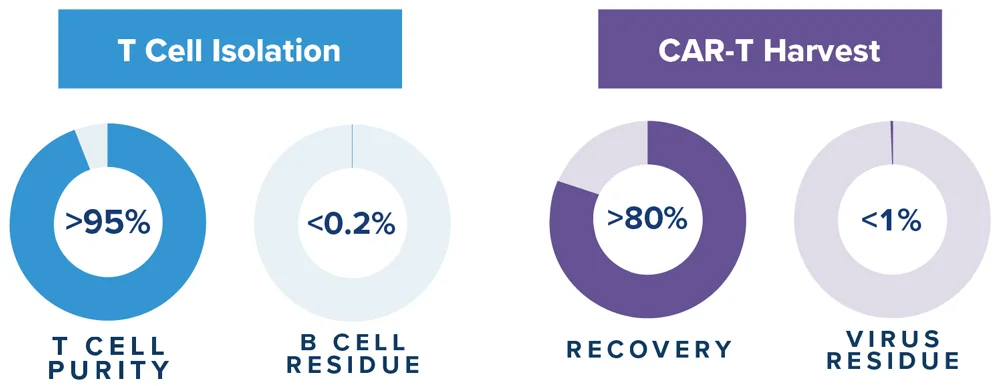

1. T Cell Isolation

- 90% purity, >70% T cell recovery

- Column-free, sterile closed system

2. Activation and Transduction

- High expression in <24 hours

- No extra buffer exchange needed

- Direct from media to transduction

3. CAR-T Harvest

- High yield, high viability

- <1% viral residue, <0.2% B cell contamination

- Formulation-ready or cryopreservation-compatible

AUTOMATION MEETS INNOVATION

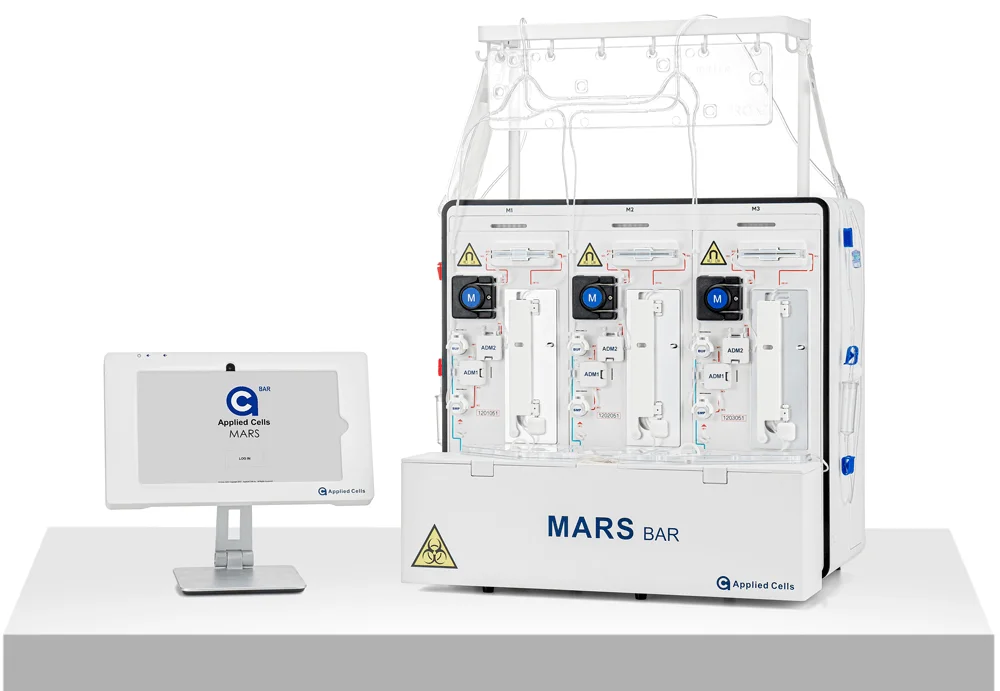

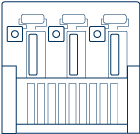

MARS® Bar – one platform for both T cell enrichment and CAR-T cell harvest

- Column-free, closed, sterile fluidics system

- ISO 13485:2016 certified and GMP-ready

- Compatible with fresh or frozen leukopak

- Solution optimized for Applied Cells’ IngenuityTM reagents

GoFast™ Results

- <72-hour workflow

- >90% purity and >70% T cell recovery

- Low viral / B cell residue

- Lower cost of goods

- High naïve stemness phenotype

- Scalable for point-of-care manufacturing

Discover All Our Products

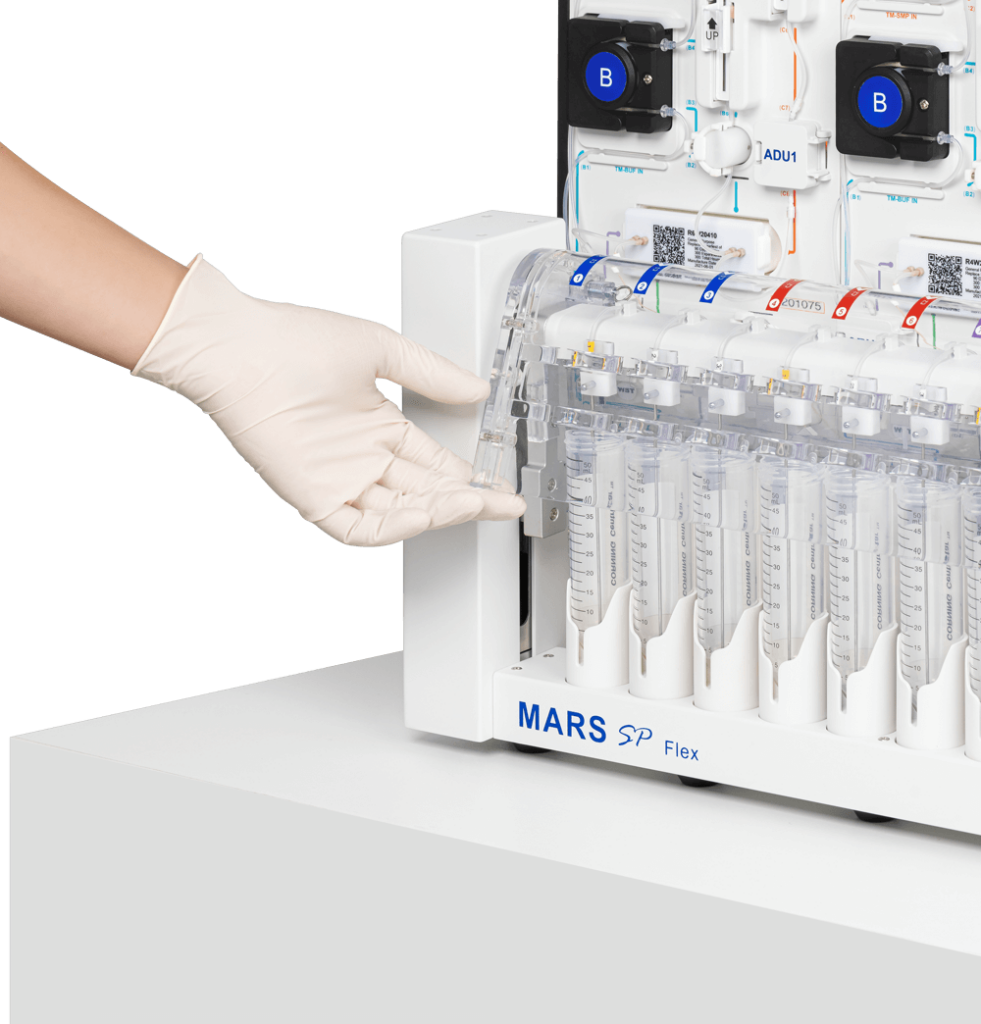

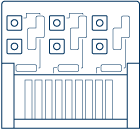

MARS® SP

Gentle acoustic debris removal for single-step, label-free cell or nuclei enrichment for up to 3 samples with ease and precision.

MARS® Bar

Positive and negative immunomagnetic cell selection with column-free technology for up to 3 samples simultaneously.

Reagents

Broad reagent selection designed and validated for exceptional purity, recovery, and viability using MARS Platform.