T cell isolation from leukopak

Accelerating cell therapy manufacturing with fast, direct processing

Simplified, high-yield T cell isolation process directly from leukopak

In CAR-T and other adoptive cell therapies, manufacturing success is often associated with efficient T-cell isolation. Leukopaks are enriched leukocyte products collected with leukapheresis process and they provide a concentrated source of starting material. However, the T-cell isolation process from leukopaks frequently requires multiple washing steps, which can lead to time consumption, complex workflows, and the risk of cell loss.

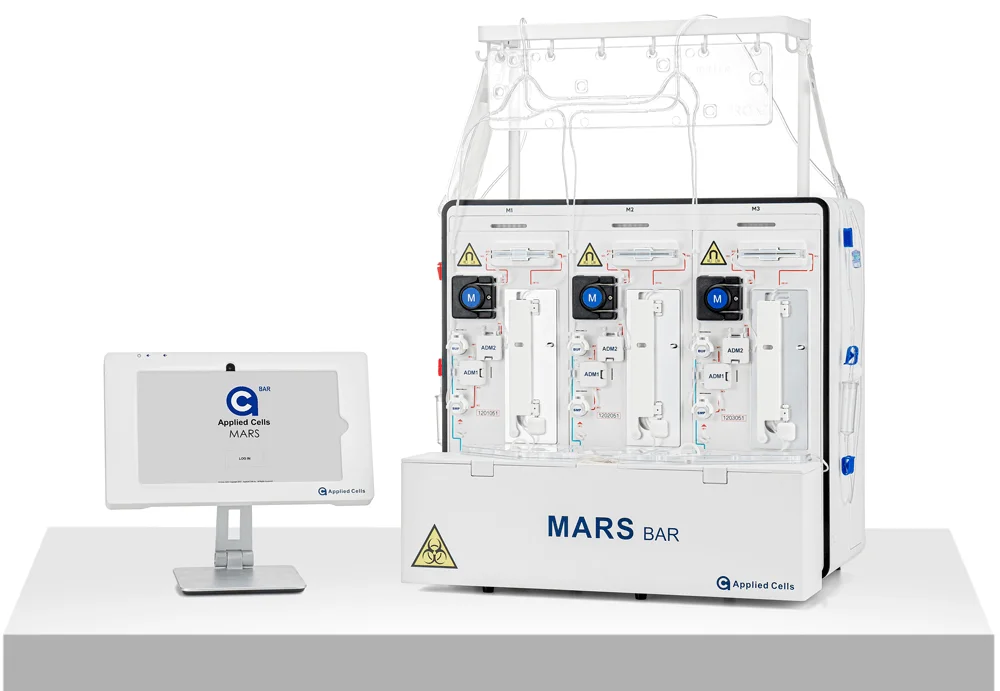

The MARS® Bar platform with Ingenuity™ 50 nm CD4 and CD8 magnetic beads enables rapid, high-purity T-cell isolation directly from leukopak, minimizing handling and preserving cell health.

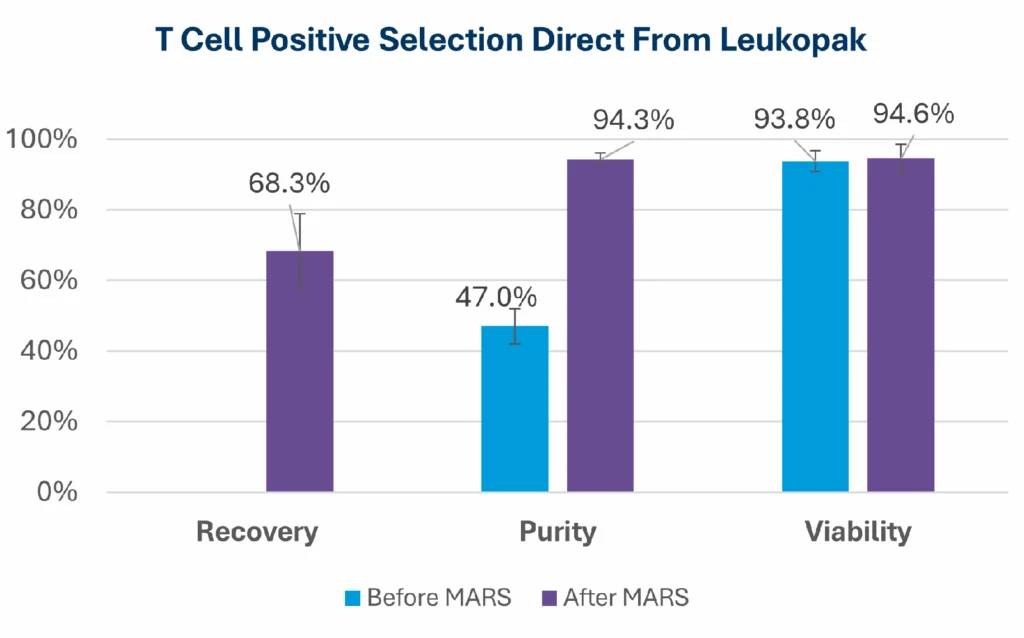

In the example below, starting from a leukopak, the MARS® Bar workflow was used to isolate T-cells 47.0% to 94.3% purity, while maintaining high viability (~94.6%) and delivering high recovery (68.3%).

Advantages of MARS® Bar direct from leukopak T-cell isolation are:

Cost-effective — no centrifugation steps; fast separation time

Efficient — high purity , yield and cell viability

Closed fluidics — GMP compliance

By integrating MARS Bar T-cell isolation directly from leukopak protocol into CAR-T manufacturing workflows, it is possible to increase manufacturing throughput, improve consistency, and reduce costs of the therapies – making them more accessible to patients worldwide.

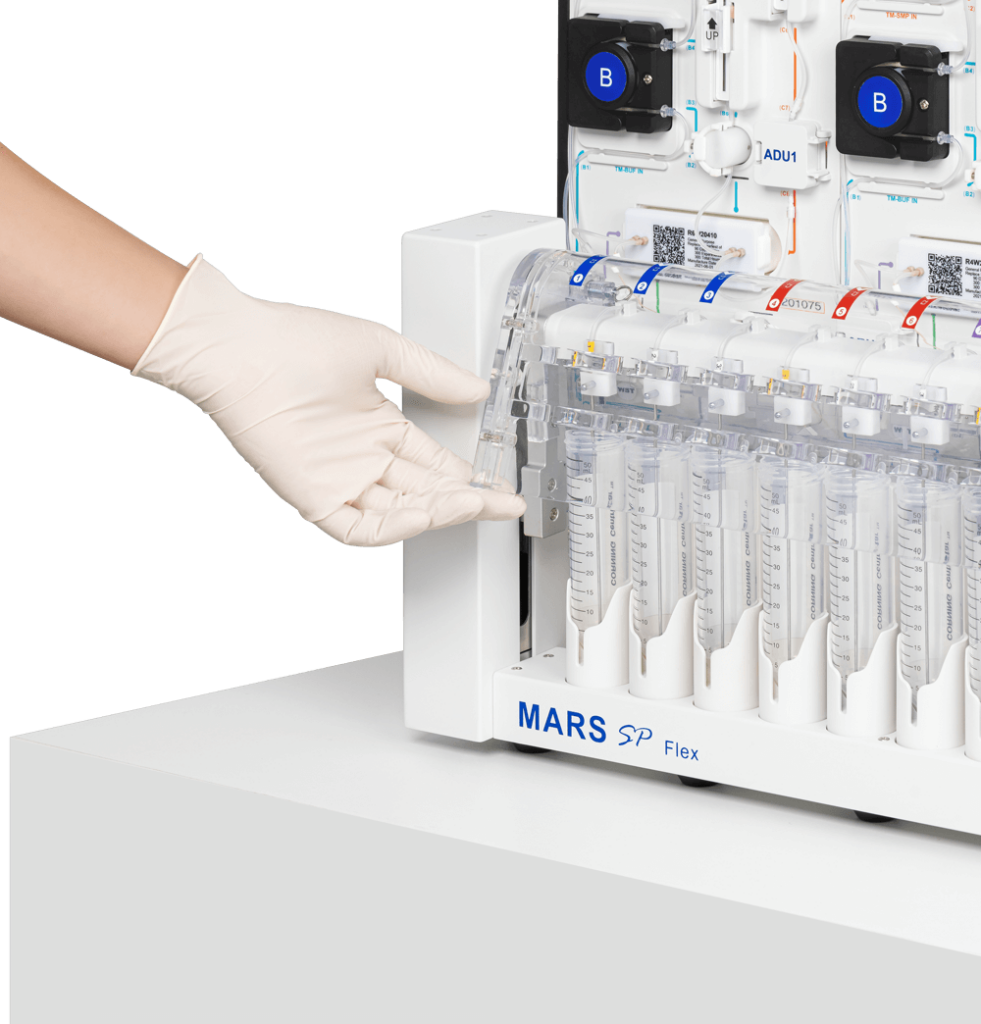

AUTOMATION MEETS INNOVATION

MARS® Bar – one platform for both T cell enrichment and CAR-T cell harvest

- Column-free, closed, sterile fluidics system

- ISO 13485:2016 certified and GMP-ready

- Compatible with fresh or frozen leukopak

- Solution optimized for Applied Cells’ IngenuityTM reagents